This also solves the mirroring issue I had previously. The steps to do this is to create two rectangles around the design, extrude the frame to the desired size, extrude the back, combine the shapes and export as an STL. I also added parameters for my design so I don’t run into the same issue. To fix the sizing issue, I increase the overall size slightly, removed the bottom and top sphere, and cut the bottom sphere just enough for a stand. The second issue was that when copying the first body in Fusion, I did not mirror the second body. The mistake I made here was not adding a parameters for the 3D shape so the indents in the rigid cast don’t protrude in the flexible mold (making it hard to have a clean cast final outcome). The final step was to go to the run tab and hit start to begin the cutting processĪfter the cutting was complete, below was the final result. After setting the jog position, I clicked the Set Zero button to zero all the axes, then clicked done. I went the “jog” tab to move the toolhead by clicking the appropriate arrow button to position the zero. Then clicked on ‘Connect Cutter’ to connect to the machine.Īfter the “initialize” screen appeared, I clicked on the ‘Initialize Machine’ button to begin homing the machine.

#Meshcam 6 program zero not working right software#

I Opened the software and connected the machine cable to the computer. To begin the milling process, I imported my Gcode to Carbide Motion, which is the control software used to operate the Nomad CNC machine. I created the toolpath again and saved both Gcode files to import in Carbide 3D. I then went back to Meshcam and repeated the steps above. to fix that, I went back into fusion, reduced the scale and removed the top sphere. I created the toolpath, however, the cut time was too much for each piece.

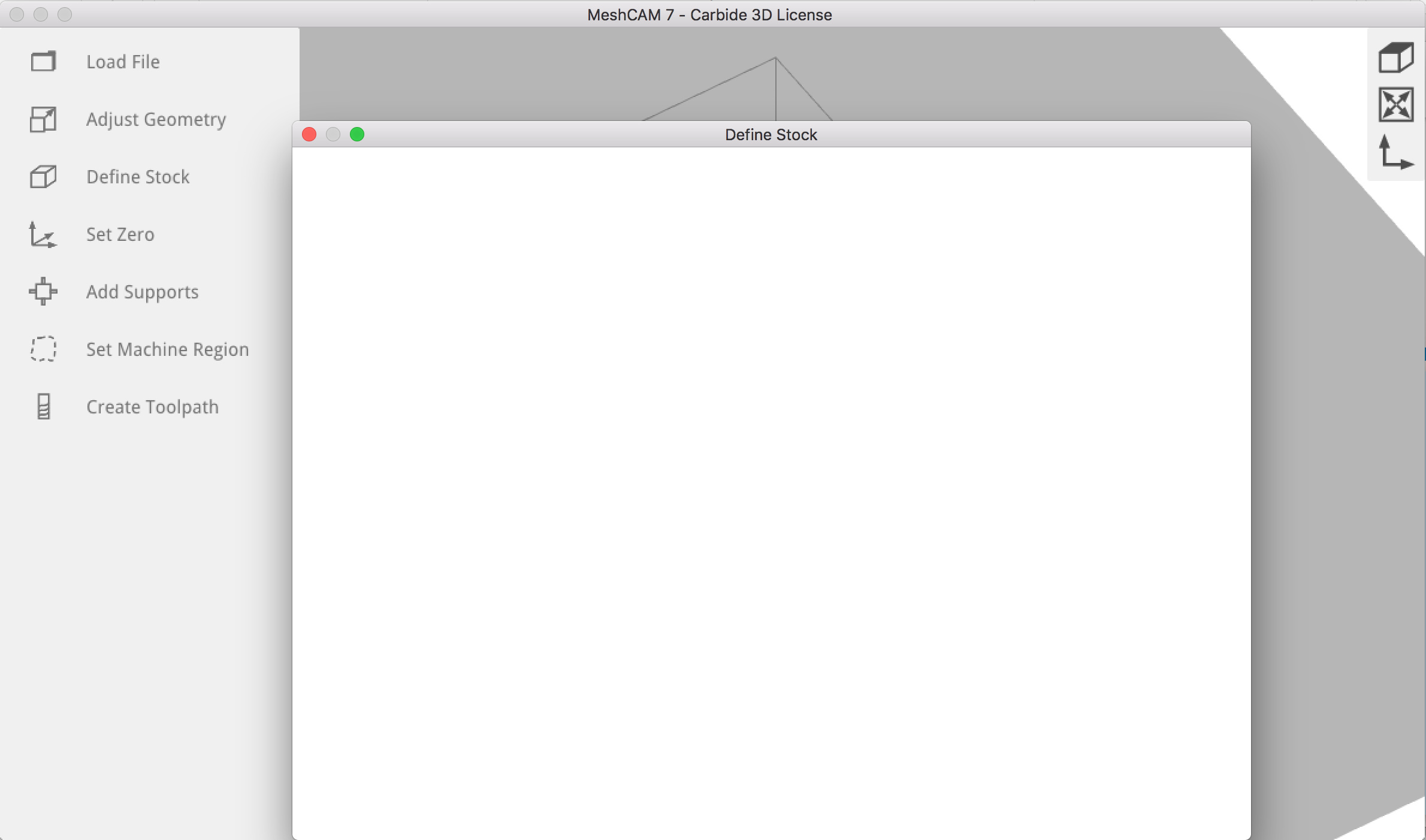

The only change was to the X position - this is so I can arrange the spacing of my geometry to the left and right of the stock I went back to fusion and exported STL files for each part and repeated the process in MeshCAM and it worked! The best option was to try creating toolpaths for each part and see if that helped. I repeated the same process in a newer version of MeshCAM but it also didn’t work. I tried looking up this issue online but didn’t find many resources. There was an error and the toolpath wasn’t generated. I kept the finish quality at 50% and and a smaller value for tolerance (for higher accuracy)Ĭlicked ok to generate the toolpath.

To make the toolpath, I used the automatic toolpath wizard and selected the 0.125 ball tool for both roughing and finishing

Set the program zero to the top of the stock and upper left side I defined my stock size and centered the X Y and Z positions To begin, I downloaded MeshCAM 6 and imported my STL file. MeshCAM generates a toolpath (.gcode) from an STL or DXF file that we can use to cut our machinable wax. I added the molding material pour spout (pipe) and extruded the jointsĬopied the body then extruded the second body joints to -18mm Sketched my design on the top plane of the extruded surface Inserted the joint dimensions and now I have the parameters I’m working in The first step is to insert my base measurements to know the dimensions I’m working with Demonstrate workflows used in mold design, construction and casting.Design appropriate objects within the limitations of 3 axis machining.Design a 3D mold around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.Please visit our lab’s for the group assignment. Make and compare test casts with each of them.Review the safety data sheets for each of your molding and casting materials.In this week’s assignment, the requirement is to design and mill a mold and then cast it to create a 3D object.

0 kommentar(er)

0 kommentar(er)